At One Industries, we understand the serious health risks posed by dust inhalation, which can lead to severe respiratory illnesses, including black lung disease, as well as cause accidents from a lack of visibility. Our dust suppression systems use ultra-fine water atomisation, a cutting-edge solution that effectively captures and suppresses dust particles. This advanced approach not only protects workers but also increases productivity by allowing them to operate for longer periods in safer, clearer environments.

ESTABLISHED IN 2013

We have been at the forefront of innovation, providing high-quality, cost-effective equipment designed to tackle the unique challenges faced by the mining and bulk materials industries.

With offices in QLD, WA, and NSW, etc, we serve clients nationwide, delivering products that ensure safety, durability, and enhanced operational efficiency.

INNOVATION DRIVES US

Innovation is at the core of One Industries. Each year, our dedicated team develops new products that push the boundaries of durability and performance. Our engineering solutions are informed by years of industry experience and a deep commitment to continuous improvement. From reducing the risk of equipment failure to enhancing safety on-site, our innovations set the standard for materials handling in Australia.

OUR WHY

OUR PURPOSE

One Industries, since 2013 an Australian-owned innovator, delivers trusted bulk material handling solutions that empower the mining industry. Guided by our IIPP Core—Integrity, Innovation, Problem-Solving, Partnership—we invest heavily in R&D to create cutting-edge products like WearTec™, SPL Belt Cleaners™, and Gen1 Dust Suppression Systems. These set new benchmark standards, delivering “longer life, higher productivity, better returns” with custom, durable designs that achieve greater impact than generic solutions, minimizing costs and maximizing safety and efficiency.

OUR VISION

We aim to lead Australia’s material handling sector with ethical, innovative solutions, pioneering next-generation technologies to support net-zero mining by 2050. Our systems, like Gen1 delivering up to significant reductions in dust risks and SPL Belt Cleaners™ driving greater maintenance savings, ensure safer, greener operations. Join us in redefining industry standards through trusted partnerships that inspire progress. “That’s Innovation, That’s One Industries.”

OUR VALUES — The IIPP Core and IP of Success

Our IIPP values—Integrity, Innovation, Problem-Solving, and Partnership—form the Core and Intellectual Property (IP) of our success. This blueprint drives our leadership in material handling.

• Integrity: We lead with honesty and transparency, building unshakable trust.

• Innovation: We pioneer smarter, low-waste solutions for a sustainable future.

• Problem-Solving: We deliver precise, tailored solutions for lasting impact.

• Partnership: We co-design with clients, driving shared success.

Guided by “Strive for Excellence,” IIPP ensures longer life, higher productivity, better returns—That’s Innovation, That’s One Industries.

OUR VALUES

INNOVATION

We continuously strive to meet and exceed industry standards with products that address current and future challenges.

SAFETY

Worker safety is paramount. Our equipment is designed to enhance operational safety and comply with the highest standards.

QUALITY

Our products are engineered for durability and long-term performance, providing exceptional value for our clients.

INTEGRITY

We stand behind our products, offering warranties and ongoing support for lasting value.

INNOVATION

We continuously strive to meet and exceed industry standards with products that address current and future challenges.

SAFETY

Worker safety is paramount. Our equipment is designed to enhance operational safety and comply with the highest standards.

QUALITY

Our products are engineered for durability and long-term performance, providing exceptional value for our clients.

INTEGRITY

We stand behind our products, offering warranties and ongoing support for lasting value.

WHAT WE DO

One Industries® offers an extensive range of materials handling solutions engineered to meet the demands of Australia’s mining and industrial sectors. By focusing on innovation, safety, and quality, we assist our clients in reducing life cycle costs and optimising performance. Here’s a closer look at the high-quality products we design and manufacture:

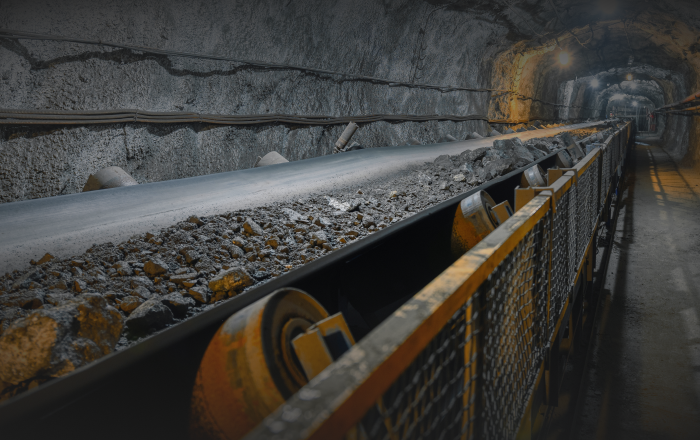

Conveyor Scraper Assemblies

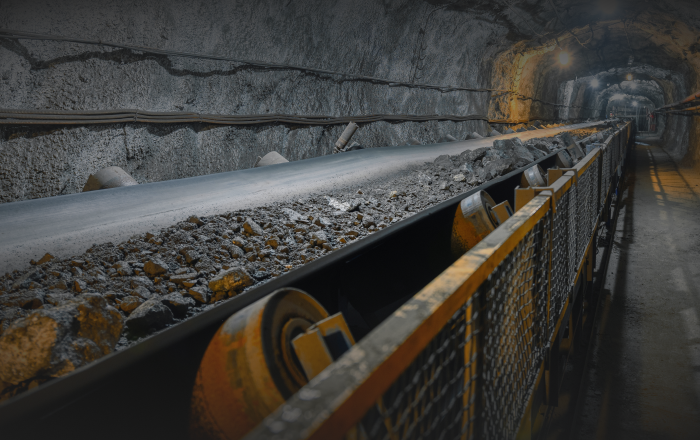

Our range of conveyor scraper systems includes primary and secondary scraper systems, along with return scraper ploughs in diagonal and V configurations. Each component is crafted for durability, designed to enhance belt cleaning and reduce the risk of carryback.

Conveyor Skirting Systems

We specialise in skirting systems with materials ranging from polyurethane to dual-seal rubber. These systems effectively minimise dust and spillage, contributing to a cleaner, safer work environment.

POLYURETHANE SCREENING

Our polyurethane screens include tensioned and skeleton screens designed for dewatering and high-frequency applications. Engineered to last longer, these screens offer exceptional wear resistance, reducing maintenance costs.

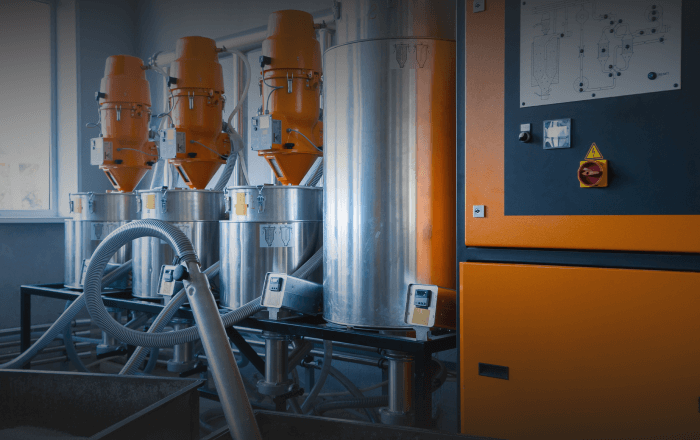

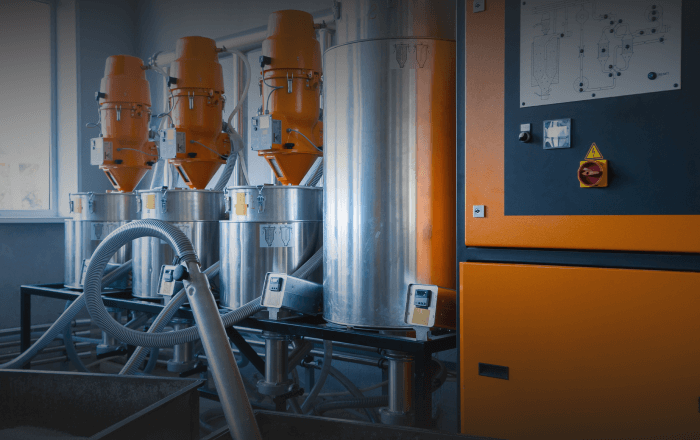

WATER CONTROL AND DUST SUPPRESSION SYSTEMS

Dust suppression is essential for maintaining a safe and compliant work environment. Our ultra-fine atomising dust suppression systems control airborne particles, protecting workers’ health and increasing visibility on-site. Additionally, our systems are designed to reduce water consumption, contributing to sustainable mining practices.

Conveyor Scraper Assemblies

Our range of conveyor scraper systems includes primary and secondary scraper systems, along with return scraper ploughs in diagonal and V configurations. Each component is crafted for durability, designed to enhance belt cleaning and reduce the risk of carryback.

Conveyor Skirting Systems

We specialise in skirting systems with materials ranging from polyurethane to dual-seal rubber. These systems effectively minimise dust and spillage, contributing to a cleaner, safer work environment.

POLYURETHANE SCREENING

Our polyurethane screens include tensioned and skeleton screens designed for dewatering and high-frequency applications. Engineered to last longer, these screens offer exceptional wear resistance, reducing maintenance costs.

WATER CONTROL AND DUST SUPPRESSION SYSTEMS

Dust suppression is essential for maintaining a safe and compliant work environment. Our ultra-fine atomising dust suppression systems control airborne particles, protecting workers’ health and increasing visibility on-site. Additionally, our systems are designed to reduce water consumption, contributing to sustainable mining practices.

MEET OUR TEAM

The team at One Industries is made up of passionate professionals committed to delivering exceptional results. Our team members bring a wealth of knowledge and expertise to One Industries, ensuring we remain leaders in Australia’s materials handling industry. Here are just a few of the key people driving our success:

MARK GILBERT

Managing Director

BRENDON BAILEY

Polyurethane Processing Supervisor

LEAH PORTER

Procurement Manager

LARRY GALVAN

Mechanical Lead Designer

DEAN BAZLEY

Operations Manager QLD

Marc Formosa

Operations Manager NSW

MARK GILBERT

Managing Director

BRENDON BAILEY

Polyurethane Processing Supervisor

LEAH PORTER

Procurement Manager

LARRY GALVAN

Mechanical Lead Designer

DEAN BAZLEY

Operations Manager QLD

Marc Formosa

Operations Manager NSW

COMMITTED TO KEEPING AUSSIE MINING STAFF SAFE

As demand for critical minerals continues to rise, mining companies must adopt advanced technology and innovative solutions to both enhance the efficiency of their operation and reduce risks to workers. Beyond moves to digitalisation such as automation, there’s a growing need for health and safety measures that safeguard workers on-site, especially when it comes to air quality and dust control. This need will soon be underpinned nationwide in the mining industry by new legislation awaiting to be introduced by the Australian Government.

The Invisible Threats – Dust and Worker Health

Water Atomisation for Underground Cooling

Our dust suppression systems also help regulate temperatures in underground mine shafts. Through water atomising mist, our systems maintain a cool, comfortable environment that enhances worker safety and productivity. Ideal for conveyor transfer points, these systems provide essential cooling while using minimal water, supporting sustainability and reducing overall water consumption.

Learn more about our Dust Suppression technology, and how it reduces the problem of Dust In Mines.

The Invisible Threats – Dust and Worker Health

At One Industries, we understand the serious health risks posed by dust inhalation, which can lead to severe respiratory illnesses, including black lung disease, as well as cause accidents from a lack of visibility. Our dust suppression systems use ultra-fine water atomisation, a cutting-edge solution that effectively captures and suppresses dust particles. This advanced approach not only protects workers but also increases productivity by allowing them to operate for longer periods in safer, clearer environments.

Water Atomisation for Underground Cooling

Our dust suppression systems also help regulate temperatures in underground mine shafts. Through water atomising mist, our systems maintain a cool, comfortable environment that enhances worker safety and productivity. Ideal for conveyor transfer points, these systems provide essential cooling while using minimal water, supporting sustainability and reducing overall water consumption.

Learn more about our Dust Suppression technology, and how it reduces the problem of Dust In Mines.

COMMITMENT TO QUALITY

One Industries® is certified under ISO 9001

This reflects our adherence to stringent quality management standards. We also meet and exceed the requirements for MDG3608 FRAS (Fire Resistant Anti-Static) Rubber & Polyurethane in our manufacturing processes. This commitment to quality ensures that our clients receive dependable, high-performing products that support safe and efficient operations.

OUR STORY

Founded in 2013, One Industries was established to create innovative belt-cleaning solutions for Australia’s mining and materials handling sectors. We recognised the challenges of carryback, dust control, and downtime, and set out to deliver solutions that address these issues head-on.

Our mission has been clear from day one: to produce durable, reliable equipment that enhances operational efficiency and safety.

Since then, we’ve consistently introduced innovative products each year, reflecting our commitment to meeting the evolving needs of our clients. At One Industries, we’re more than just a supplier – we’re a trusted partner. With 24/7 support and on-demand product availability, we minimise downtime and maximise productivity for our clients.

Our reputation for quality, reliability, and safety is well-earned, thanks to our continuous focus on improvement and our dedication to supporting Australia’s industries with solutions that stand the test of time.