WELCOME TO THE REVOLUTION

Innovation is what drives us at One Industries®.

Our engineers work tirelessly to push the boundaries of what’s possible, solving long-standing challenges the industry once accepted as unsolvable. Creating critical upgraded equipment that effectively outperforms and outlasts many similar products on the market.

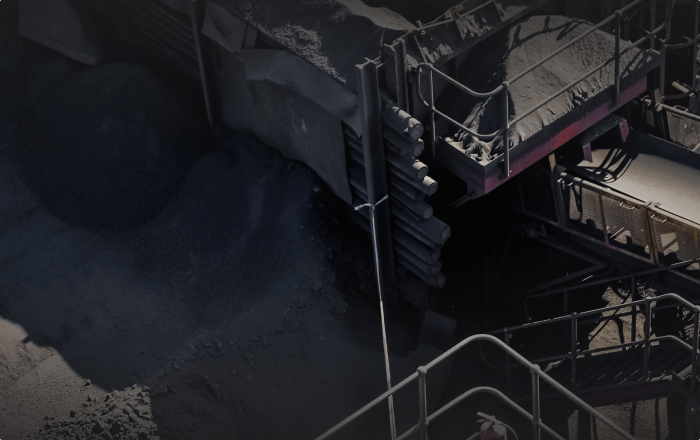

As a key player in Australia’s mining and bulk material handling sector, we’re committed to helping mining companies meet critical demands while ensuring worker safety and reducing costs associated with material waste, spillage cleanup, and equipment maintenance.

We’re here to set a new standard in operational expectations and opportunities. At One Industries, our engineers stand behind our promises, with lab-verified solutions and proven results in real-world case studies.

Discover the One Industries® difference

Innovation

Pioneering solutions that anticipate industry shifts and raise the benchmark.

Safety

Protecting people through designs that prioritise workplace safety.

Quality

Reliable, durable products built for consistent, long-term results.

Integrity

Backed by warranties and ongoing support you can trust.

Supporting Australia's Critical

Bulk Material Sectors

SURFACE MINES

While surface mines have better sunlight, controls in place are important to ensure proper visibility, better air quality and material spillage or build up that leads to more costs, downtime, and additional work.

UNDERGROUND MINES

No light, confined spaces, and far beneath the surface. Underground coal mines are a harsher work environment and demand stricter safeguards to protect workers, such as durable FRAS rated conveyor components.

PORTS

Ports and terminals operate under intense pressure to maintain fast turnaround times while managing the hazards of heavy equipment, airborne dust, material spillage, and exposure to harsh marine environments. These high-demand settings must balance operational efficiency with worker safety, environmental protection, and regulatory compliance–often all at once.

we're committed to innovation

RELEASING NEW PRODUCTS INTO THE MARKET EACH YEAR

SOLVING ENVIRONMENTAL AIRBORNE DANGERS ON MINE SITES

DUST SUPPRESSION

Our Ultrasonic Dust Suppression Systems atomise water into a mist to capture and suppress harmful airborne dust particles in surface and underground mines.

Atomises water to a fine mist

Substantial water reduction by design

IP65 rated enclosure using Air and water atomisation

AIRBORNE DUST

The large environmental impact and the invisible dangers on mining sites

The fine particles airborne in mining sites pose serious health risks to workers when inhaled. On top of these risks of respiratory damage, other hazards arise on the worksite from decreased visibility. Meaning more people are likely to take out slip trip and fall. Mining dust also may be far reaching, settling into other areas in the radius of the plant, and impacting residents and important natural environments and ecosystems.

LUNG SCARRING

Coal dust exposure over time can cause scarring in the lungs and make it harder to breathe

‘BLACK LUNG DISEASE’

Coal dust in particular is notorious for causing ‘Black Lung Disease,’ (pneumoconiosis)

OTHER HEALTH CONDITIONS

Airborne dust particles can also lead to workers developing silicosis, asbestosis or bagassosis

AFFECTS EQUIPMENT PERFORMANCE

These particles also exacerbates wear and tear on output and equipment

GET AHEAD OF REGULATORY PRESSURES

Mining companies and industry bodies are facing increasing pressures from regulators and environment groups to implement greater controls to suppress dust on worksites.

OUR SOLUTION

DUST SUPPRESSION

SYSTEMS

Spray bars contribute to solving carryback by spraying high-pressure water jets directly onto the conveyor belt, clearing away materials that could otherwise build up. Positioned close to the belt, spray bars help keep the belt clean, lower maintenance needs, and reduce wear on key parts, which helps extend the life of conveyor components and keeps operations running smoothly.

By using spray bars near discharge points, you can stop spillage before it starts. The high-pressure water jets clear away loose material, protecting work areas from dangerous debris and reducing the need for constant clean-up. Spray bars also support other solutions like conveyor skirting, which further keeps spillage in check.

Material build-up along conveyor belts and components can slow down operations and wear out equipment faster. Spray bars, with their focused water jets, keep materials from sticking to the belt and other parts. Placing spray bars along the belt’s return side ensures a steady rinse-off that helps avoid downtime for maintenance and extends the life of conveyor components. This keeps the conveyor moving efficiently and reduces strain on motors, helping the system work at its best.

MITIGATE CARRYBACK

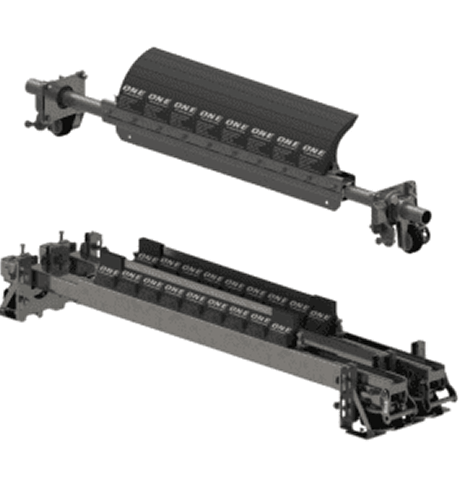

CONVEYOR BELT CLEANING SYSTEMS

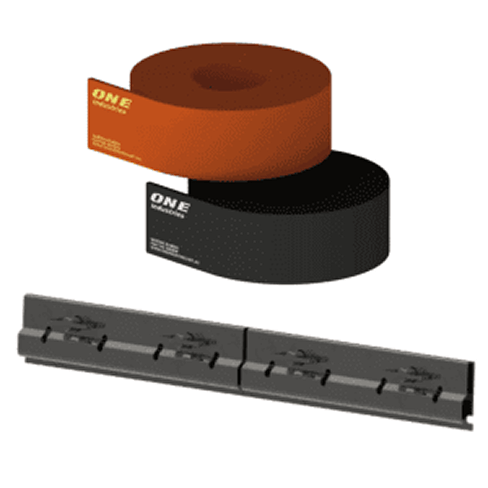

One Industries’ own Primary & Secondary Conveyor Belt Cleaning systems mitigate carryback, mistracking, and material build-up. The system’s automatic real-time adjustments of the blade-tip angle mean optimal scraping on the belt, to crack down on product loss and ensure even wear for your operation (no matter the conveyor belt configuration or the bulk materials).

One Industries Conveyor belt cleaners can be upgraded to Weartec Polyurethane.

Carryback is what happens when materials stick on the conveyor belt, past the point of discharge and return to the front of the machine. This causes product spillage and build-up in conveyor belt systems; and bringing additional costs to clean up, service equipment and in product loss. Our conveyor belt cleaning solutions thoroughly cleans the belt from any sticky residue materials to cut back on carryback. Ensuring less spillage, material build-up and damage on supporting conveyor belt components

High performance conveyor belt cleaners are critical in reducing spillage for conveyor belts. Any materials that fall off the belt and accumulate around the conveyor is spillage. This loose fugitive material can cover idle rollers, conveyor parts, or structural supports. All of which lead to expensive clean-up and replacement costs, from the build up. Spillage particularly puts idle rollers at risk, making them more susceptible to jamming and causing more friction on the conveyor belt.

SPL conveyor belt cleaners provide system output data for blade wear, vibration analysis, pressure transducer, and spray bay water consumption. Bringing your team better insights for operational efficiency.

An idler is an important non-powered support component of a conveyor belt system. Idlers are the rolling component attached at either the carry or return end of a conveyor belt. When idlers fail, buried or clogged fugitive materials from the belt are usually the culprit. Increasing the lifespan of idlers requires a thorough conveyor belt cleaning and sealing (skirting) solution to cut down on Spillage and Carryback. Seized or frozen idlers need to be removed and fixed promptly, as increased exposure damages the conveyor’s belt and motor. This is a difficult task as it involves handling the heavy weight of the idlers and the conveyor belt itself, as well as hazardous work environments: at heights, in confined spaces, and in heated areas that put workers at risk of heat stroke.

Live capacity refers to the actual usable portion of belt capacity that’s actively carrying material on the conveyor at any given moment. It is often a fraction of the total belt capacity, considering the potential variations in material load, distribution, belt tension, and the need to account for factors like belt sag, or spillage. Reduced live capacity from mismanagement can lead to uneven and increased wear; as well as misalignments that cause spillage, belt wear and structural damage.

Coal or ore can easily build up on conveyor belts or system components, in the form of residue, clumps, lumps, debris around pulleys and rollers, or accumulated dust. The consequences of this build up are wide reaching from capacity loss, interruptions to operations, increase wear and tear, frequent down tone, increased need for manual cleaning, higher slip and trip hazard, fire and overheating risk, impact on belt alignment and tracking, as well as health concerns from increased airborne dust particles.

Inspection Doors: Cover moving parts that can otherwise be a mechanical hazard, while offering ease of access for visual inspection, sampling and servicing.

Our conveyor belt cleaning systems also offer safety, with easily retractable modular cartridges for inspection and maintenance. Making it safer and simpler for service operators.

GAIN THE EDGE WITH

WEARTECTM Polyurethane Belt Blades

Specially formulated polyurethane compositions by our engineers, that substantially outperforms most other conveyor belt cleaning blades on the market. These FRAS belt blades are a critical component of our conveyor belt cleaning systems and are a critical requirement in underground mining environments.

EXCEPTIONAL DURABILITY

3-6x more durable than traditional blades.

COST EFFICIENCY

Helps greatly reduce weekly product loss from carryback.

PERFORMANCE

Advanced polyurethane composition ensuring superior wear resistance, abrasion resistance, and impact resilience for rigorous mining conditions.

CLEANING EFFICIENCY

Safer, thorough cleaning reduces downtime.

SAFETY

Exceeds stringent FRAS (Fire Resistant & Anti Static) Australian safety standards for hazardous environments.

LAB-TESTED RELIABILITY

Rigorously tested and validated, WearTec™ delivers consistent and dependable performance in demanding applications.

EXCEPTIONAL DURABILITY

3-6x more durable than traditional blades.

COST EFFICIENCY

Helps greatly reduce weekly product loss from carryback.

PERFORMANCE

Advanced polyurethane composition ensuring superior wear resistance, abrasion resistance, and impact resilience for rigorous mining conditions.

CLEANING EFFICIENCY

Safer, thorough cleaning reduces downtime.

SAFETY

Exceeds stringent FRAS (Fire Resistant & Anti Static) Australian safety standards for hazardous environments.

LAB-TESTED RELIABILITY

Rigorously tested and validated, WearTec™ delivers consistent and dependable performance in demanding applications.

Services

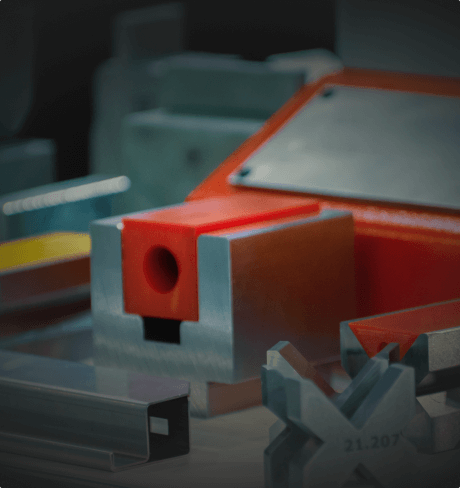

POLYURETHANE MOULDING

One Industries has the capabilities to design and mould your polyurethane needs for your company with our custom moulding services. Harness our advanced technology, extensive industry insight, and specialised polyurethane formulations for industrial use, for a solution that is best tailored to your application.

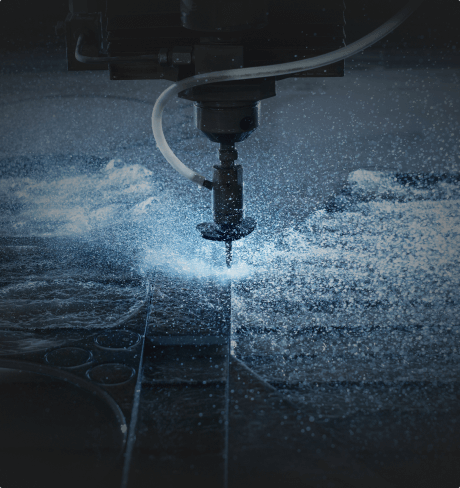

WATER JET CUTTING

Water jet cutting is able to create basic, intricate and 3-D design cuts with extreme accuracy, without heat damage, for a wide range of materials. We offer fast, cost-efficient precision cutting for the mining, manufacturing, and agriculture sectors.

Products

Shop all products

Conveyor Belt Cleaners

Dust Suppression

Air Control Systems

Conveyor Belt Skirting

LATEST UPDATES

Queensland Mining & Engineering Exhibition (QME) 2024 in Mackay

We were present at the QME 2024 this year to introduce our latest cutting-edge solutions to the market. One Industries will also be present for QME 2025, next year.

But if you’re curious about what we do and how our innovations can change things for your worksite, you don’t have to wait until then. Call 1300 551 344 and we can arrange a personalised discovery session at your convenience.

Blog

View all

Maintenance and Care of Dust Suppression Systems

Water Conservation in Dust Suppression